Silicon has had a very good run: The semiconductor is the MVP material of the last half century, enabling solar cells, computer chips and a whole array of electronic devices that define modern life.

Chang-Beom Eom

Chang-Beom Eom

Now, the future of electronics is going to require new classes of advanced materials—yet those materials are much more difficult to produce than silicon.

One emerging class of material is complex oxide heterostructures, in which extremely thin films are layered on top of one another. This layering produces exciting properties like superconductivity and unique types of magnetism at the interfaces, or the tiny regions where the materials interact with one another.

One standout heterostructure identified by researchers is lanthanum aluminate and strontium titanate, or LaAlO3/SrTiO3. When the materials are layered together, researchers can sketch conductive patterns on the interface with an atomic force microscope, which previously has enabled them to fabricate nanoscale structures like single-electron transistors, electron waveguides and photodetectors.

However, until now, LAO/STO hasn’t been particularly thin. Strontium titanate is usually synthesized as a relatively thick crystal slab, making it difficult to integrate the sandwich of materials into electronics or to stack it with other heterostructures.

That’s why Chang-Beom Eom, a professor in the Department of Materials Science and Engineering at the University of Wisconsin-Madison, recently developed a new method for producing extremely thin, free-standing LAO/STO membranes, which can be integrated into other heterostructures and even into silicon-based nanoelectronics. The research appears in the Aug. 13, 2021, issue of the journal Science Advances.

“The two-dimensional LAO/STO interface used to sit on top of a rock of material, the strontium titanate. What we wanted to do is lift off the functional part that is superconducting and free it from the substrate,” explains Jeremy Levy, co-author and director of the Pittsburgh Quantum Institute. “Then maybe it could be integrated with graphene or with other materials. To do that required overcoming enormous challenges—just the kind of challenges Chang-Beom likes.”

To produce the LAO/STO thin film, Eom, a thin film synthesis expert, deposited a high-quality 20-nanometer sacrificial layer of strontium ruthenate on top of a strontium titanate substrate using a technique called pulsed laser deposition.

Jeremy Levy

Jeremy Levy

His team then deposited a 200-nanometer layer of strontium titanate on top of that, specially treating it to make it titanium-dioxide-terminated. Over that layer, the team deposited an extremely thin lanthanum aluminate film.

They then soaked that multilayer film in an aqueous solution of sodium periodate to remove the strontium ruthenate layer. After two days, a super-thin, freestanding LAO/STO membrane floated to the surface. The researchers then mounted it on a flexible aluminum oxide substrate, creating an extremely thin oxide heterostructure that incorporated the essential oxide interface.

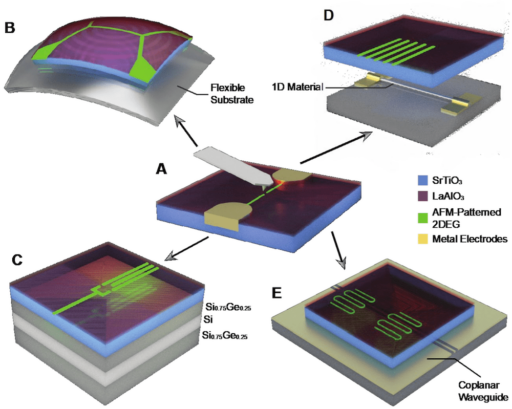

A new, thin LAO/STO membrane has many potential uses as a component in flexible electronics, quantum dots, microwave waveguides and other nano electronics.

A new, thin LAO/STO membrane has many potential uses as a component in flexible electronics, quantum dots, microwave waveguides and other nano electronics.

Other groups have attempted to synthesize thin LAO/STO membranes, but with limited success. Eom says the secret to his method is the quality of the crystal layers produced by his synthesis techniques, which minimize defects in the crystals, preserving their unique properties. The use of the sacrificial layer was also an important innovation. “The challenge is not only making the membrane, but we had to make a high-quality, atomically smooth single-crystal membrane,” says Eom. “An important advance was the strontium ruthenate sacrificial layer. Now that the technique is out there, I hope other people read this paper and are able to make it, too.”

Levy, who has worked with bulkier LAO/STO heterostructures for years, tested the material, finding that the freestanding membrane had the same properties as its thicker predecessors. The synthesis of this film opens up many possibilities, from stacking LAO/STO films into complex heterostructures with other materials like graphene or integrating them into quantum computers and quantum dots, among many others.

“This is an intersection. You can go left, right, up down; it’s really something that is going to take us in a whole bunch of directions at the same time, limited only by funding and personnel,” says Levy. “We’re very excited about this result because it’s bringing together major themes in material science, nanoscience and quantum information. We’re showing a way to enable new technologies through materials advances and taking big themes like 2D materials and combining them with complex oxides.”

Chang-Beom Eom is Raymond R. Holton Chair for Engineering and Theodore H. Geballe Professor in materials science and engineering at UW-Madison.

Other UW-Madison authors include Kitae Eom, Hyungwoo Lee and Jung-Woo Lee.

Muqing Yu, Dengyu Yan, and Patrick Irvin of the University of Pittsburgh and Jinsol Seo and Sang Ho Oh of Sungkyunkwan University in the Republic of Korea also contributed to this work.

This work was supported by the Gordon and Betty Moore Foundation’s EPiQS Initiative under grant GBMF9065, Vannevar Bush Faculty Fellowship (N00014-20-1-2844 (C.B.E), N00014-15-1-2847(J.L.), the US Department of Energy (DOE), Office of Science, Office of Basic Energy Sciences (BES), under award number DE-FG02-06ER4632, AFOSR (FA9550-15-1-0334 (C.B.E)), NSF through the University of Wisconsin MRSEC (DMR-1720415), PHY-1913034 (J.L.), ONR N00014-20-1-2481 (J.L.), and ONR MURI (N00014-21-1-2537) (J.L., C.B.E).