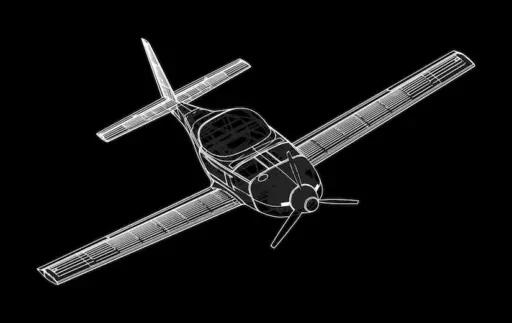

In fall 2020, a new, sleek cutting-edge aircraft will take its maiden voyage in the skies over Madison, Wisconsin, when the DarkAero 1 begins test flights at the Dane County Regional Airport. But the jet-black two-seat prop plane could just as easily be called the BuckyAero. The aircraft’s designers are three brothers, Ryley, Keegan and River Karl, all of whom graduated from the University of Wisconsin-Madison College of Engineering and are intent on disrupting the kit aircraft industry.

The Karl brothers grew up hearing stories about airplane construction from their grandfather, an engineer at Boeing, and they spent long hours putting together model airplane kits as kids. The three had always talked about going into business together, and even developed a Google document full of potential ideas. But as they graduated from college, they found themselves working for different companies in different industries.

In 2011, Ryley (BSEM ’08), who majored in aeronautical engineering, rejoined his brothers in Madison after working in hydraulic systems R&D for Caterpillar in Decatur, Illinois. He brought with him a kit aircraft he’d been putting together for fun. In their spare time, Keegan (BSME ’10) and River (BSEE ’12) pitched in to help build the plane. As the aircraft slowly came together, the brothers realized that many of the materials and designs in the kit were outdated or could be improved using modern engineering tools.

“We had talked about teaming up on something for a long time, and because of our broad coverage in mechanical, aeronautical and electrical engineering, we thought we could do something very interesting,” says Ryley. “I’m not sure who suggested it, but we started talking about developing our own kit. There wasn’t anyone in the market doing long-range, high-speed aircraft.”

The plane itself has an infusion-molded frame made of composite materials—unique in the kit aircraft world—which in the past would have required a multi-million-dollar autoclave to produce.

The plane itself has an infusion-molded frame made of composite materials—unique in the kit aircraft world—which in the past would have required a multi-million-dollar autoclave to produce.

While most commercial aircraft are built 100-percent in a factory certified and inspected by the Federal Aviation Administration, kit aircraft—also known as home-built or experimental aircraft—are assembled by amateur builders who usually buy the kits from small manufacturers. Legally, to qualify as an “experimental” aircraft (the legal term for home-builts), a hobbyist must construct at least 51 percent of the craft. Typically, it takes 1,000 to 3,000 hours to build a kit aircraft, a process that can take several years of tinkering in a garage.

When they began to study the kit aircraft industry, the Karl brothers found that most designs were decades out of date, with none using state-of-the-art materials or tools. And none of those filled the long-range, high-speed niche.

The brothers believed that by using modern manufacturing techniques, they could drop the price point of their kit plane while also improving its performance over other kits in the market. In 2014, they worked nights and weekends putting together plans for DarkAero. In 2017, they quit their day jobs and all three began working full time on the project at a rented hangar at the Dane County Regional Airport in Madison. In fall 2020, they will finally have the first DarkAero 1 prototype ready for testing and hope they can begin delivering kits to customers sometime in 2021.

While modern aerospace firms use some of the most sophisticated engineering tools available, the brothers say that those high-tech processes have not trickled down to amateur aircraft. “The designs on the market were implemented one, two or three decades ago using the best tech at the time,” says Ryley. “But there hasn’t been a fresh attempt using all new tech. That’s a big part of what we’re doing, taking these new tools and improving home-grown aircraft to push the industry forward.”

Those tools include using CAD and 3D modeling to develop the plane and simulation tools to model the designs using computational dynamics and virtual wind tunnels. The brothers are also using state-of-the-art CNC machines to cut out parts and make dimensionally accurate molds. They’ve used 3D printing to create some specialized parts. The plane itself has an infusion-molded frame made of composite materials—unique in the kit aircraft world—which in the past would have required a multi-million-dollar autoclave to produce.

The result of the advanced design process and materials is a plane that will be faster, lighter and more efficient than anything currently on the market. The DarkAero 1 has a 23-foot wingspan, a cruising speed of 275 miles per hour and can fly 1,700 miles. “The DarkAero is smaller and more aerodynamically clean than other kit aircraft and achieves really good performance targets without as big of an engine or burning as much fuel,” says River.

If it hadn’t been for their education at UW-Madison, the brothers say DarkAero wouldn’t exist. Keegan says several lab courses he took apply directly to his daily work creating engine mounts and molding composites. His extracurricular participation on the hybrid vehicle team at the university also gave him hands-on experience in wiring the plane. Ryley says his entire undergrad experience, which included calculating airplane performance, working with wind tunnels and even designing an airplane for his senior project, laid the groundwork for the DarkAero 1. River believes that exposure to the tools and software used in modern engineering during their undergrad years gave them an edge. “If you don’t have that, you don’t even know these tools exist,” he says. “We were exposed to skills that we didn’t have to learn on our own.”

The preliminary designs for the plane have convinced the hobbyist community that the DarkAero is the real deal, and the company currently has 43 deposits for aircraft. The three brothers will build the $79,900 kits themselves, producing a handful the first year, then double production the year after, hiring more labor as they perfect their manufacturing processes.

While they are completely focused on getting the DarkAero 1 airborne, the Karl brothers say they are interested in producing more designs in the future. Ryley points out that Cirrus Aviation, a company that now manufactures small jets, began as two brothers making kit airplanes in Baraboo, Wisconsin. “Basically, we’d like to follow the same formula,” he says. “We’re right now at ground level but laying a path if we want to pursue something like that.”